Textile Fibers: Innovation to Improve Their Technical Properties

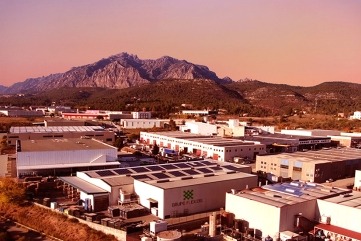

At Flexicel, we believe in constant innovation and development to enhance the technical properties of the materials that are part of our daily lives. Among these, textile fibers hold a prominent place, not only because of their wide variety of applications but also because of the possibilities they offer to optimize their performance through advanced technologies.

Textile fibers, whether natural like cotton and wool, or synthetic like polyester and nylon, have characteristics that can be enhanced to deliver better performance in various industries. By adding additives or applying specialized treatments, their resistance, durability, and other key properties, such as protection against abrasion or fire, can be significantly improved.

Natural Fibers: Cotton and Wool

Cotton is one of the most widely used fibers globally, valued for its softness, absorbency, and versatility. However, cotton can benefit from reinforcement treatments to improve its abrasion resistance, extend its durability, and offer properties like fire resistance, making it ideal for applications in sectors where safety is paramount.

On the other hand, wool, renowned for its insulating and thermal qualities, can be treated to become even more effective in environments that require greater wear and heat resistance. By incorporating fire retardant additives, wool can be used in high-risk situations, increasing its ability to withstand fire without compromising its thermal properties.

Synthetic Fibers: Enhancing Their Performance

Synthetic fibers like polyester and nylon already have technical characteristics that make them popular in industrial applications. They are highly resistant and durable but can also be improved by adding technical treatments that boost their abrasion resistance and increase their lifespan in extreme conditions. For example, by using fire-repellent additives, these fibers can become safer in applications where exposure to extreme temperatures or fire risk are key factors. Additionally, acoustic treatments can enhance their sound-absorbing capabilities, making these fibers more efficient in projects where noise control is essential.

Abrasion and Fire Resistance

One of the greatest advantages of improving textile fibers is their ability to withstand conditions that could damage or compromise their functionality. In industrial and construction sectors, abrasion resistance is crucial to ensuring the longevity of textile materials. Surface treatments that reinforce these fibers make them more suitable for enduring continuous wear, maintaining their structural integrity for longer periods.

Similarly, fire resistance is an essential quality in many industrial and construction environments. Thanks to fire retardant additives, textile fibers can significantly increase their capacity to withstand high temperatures, reducing the risk of fire spread and offering greater safety for both end-users and the projects they are used in.

Acoustic Properties: Silence as an Advantage

In addition to mechanical and thermal resistance, another area where textile fibers can excel is in their acoustic properties. The use of sound-absorbing treatments or acoustic additives transforms these fibers into key tools for noise reduction. In applications ranging from architecture to interior design, textile fibers with good acoustic properties can enhance comfort by absorbing sound and reducing echo, making them an ideal option for environments where noise control is a priority.

Innovation in Service of Sustainability

At Flexicel, we are dedicated to seeking sustainable and efficient solutions that not only improve material characteristics but also contribute to a smaller ecological footprint. The technical improvement of textile fibers through specialized treatments prolongs their lifespan, reducing the need for frequent replacement and minimizing waste. At the same time, these solutions can be efficiently integrated into sustainable manufacturing processes, optimizing resource and energy use.

Textile fibers, both natural and synthetic, offer a wide range of applications that can be enhanced through the addition of additives and technical treatments. At Flexicel, we are committed to developing innovative solutions that reinforce the properties of these materials, ensuring their abrasion resistance, fire resistance, and optimizing their acoustic qualities. With every new advance, we aim to not only improve product performance but also contribute to a safer, more efficient, and sustainable future.

To learn more about the advanced materials and solutions we offer at Flexicel, we invite you to visit our website and discover our wide range of products designed to meet the most demanding technical needs: https://grupoflexicel.com/es/materiales